DESCRIPTION

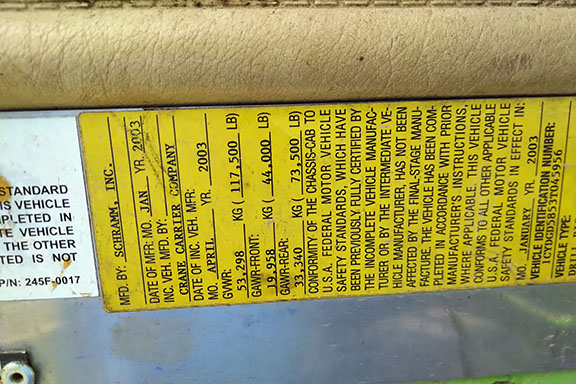

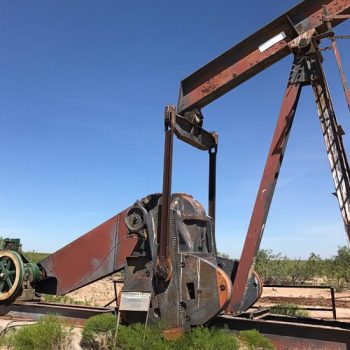

The 2003 Schramm T130XD Drilling Rig is equipped with an MTU 12V2000 engine. With 1,883 hours since it was installed new. The 2003 Schramm T130XD Drilling Rig has most of the necessary parts to reinstall the original Sullair 1350XH-1150XHH air compressor system, but the airend requires rebuilding.

Key features of the drilling rig include:

It has a substantial pullback capacity of 130,000 pounds, making it capable of handling demanding drilling tasks. The rig features a non-tilt high torque two-motor spur gear powerhead, which provides efficient drilling power and control. It is equipped with a floating cushion substructure, which helps with stability and support during drilling operations.

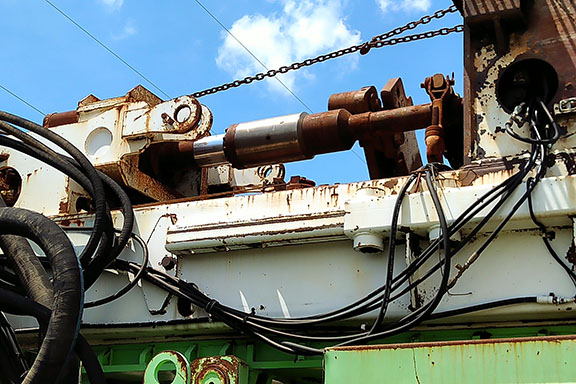

The rig is set up for single rod loading and is compatible with IR RD20-style drill pipes. Making it versatile for various drilling applications. It includes an FMC 18 GPM water injection pump, which is essential for drilling operations that require water for lubrication or cooling. We replaced 90% of the hydraulic hoses in 2016, and rebuilt five hydraulic pumps. All to ensuring the reliability and performance of the hydraulic system.

This Schramm T130XD drilling rig appears well-maintained and suitable for various drilling projects. With the capability to handle significant pullback and compatibility with different types of drill pipes. However, it’s worth noting that the airend for the air compressor system will need rebuilding, which may require some additional maintenance work to bring the rig to optimal operational condition.

ABOUT SCHRAMM SERVICES

From Schramm’s website:

“Schramm is a US and Australian manufacturer and global supplier to the hydraulic drill industry. We focus on land-based applications and specialize in mobile, top-head, hydraulic rotary drilling.

Schramm supplies companies in the mineral exploration, grade control, water well, geothermal, construction, and oil and gas sectors worldwide.”