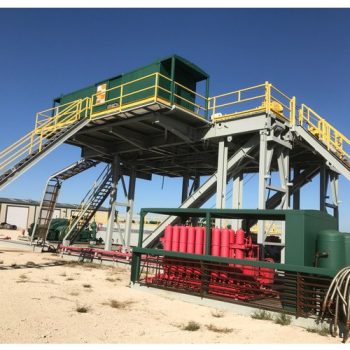

Serial Number 21081 T3W Deephole Drill

6,633 Original Operational Hours

Atlas Copco Manufactured in Garland, Texas USA (Ingersoll-Rand / Atlas Copco / Epiroc)

Mounted on an International 5000 Paystar (Navistar) Chassis

Heavy Duty reinforced high strength steel Double Frame full length of chassis

4 Hydraulic Outrigger Stabilizer Jacks, 2 behind cab (mid Frame) allows front hood access and 2 at

drilling end

Over pressure control system on jacks

2-speed high torque / high speed top head drive with 4 motors

Cyclone style pipe handling and retract system to provide clear centralizer access

20” hydraulic open and close and swinging open and close access to the centralizer bushings.

Air operated table breakout wrench, and air operated retract access gates

Hydraulic powered breakout wrench

6 – rod carousel for 4-1/2” diameter drill pipe providing 20” clear access in derrick/mast/tower

structure to handle casing

Braden CH230A high torque / High Speed Hydraulic powered Main Winch 18k bare drum single line

Ingersoll-Rand HR2.5 Over Under 2 stage oil flooded screw compressor 1070 cfm at 350 psi free air

delivery

Powered by Caterpillar C15 Diesel Engine 1800 RPM 565 HP high duty cycle Industrial Engine

In-Out Box Disconnect Device between Engine and Compressor

25 GPM Water Injection with variable speed control

7 Gallon DHD Lubricator (Hammer Oiler) 3 displacement settings

Jib Boom for main winch line with dual controls, swing and extend capabilities

Single Rod Loader and Rod Storage Box

Under Deck high capacity Fuel Tank for Deck Engine

Under Deck Tool Box

Total Rod Storage of 500 ft. (25 pieces of 4-1/2” X 20 ft. Cyclone style flush joint Drill Pipe)